Post Author:

Blink Juwele

Categories:

Date Posted:

February 18, 2023

Share This:

The process of creating stainless steel jewelry

Discover the intricate process of creating stainless steel jewelry, from the initial design to the finished product. Learn about the different techniques used by skilled craftsmen and the cutting-edge technology used to create intricate and beautiful jewelry pieces. Gain an appreciation for the artistry and precision required to produce stunning stainless steel jewelry.

Welcome to the World of #Blink

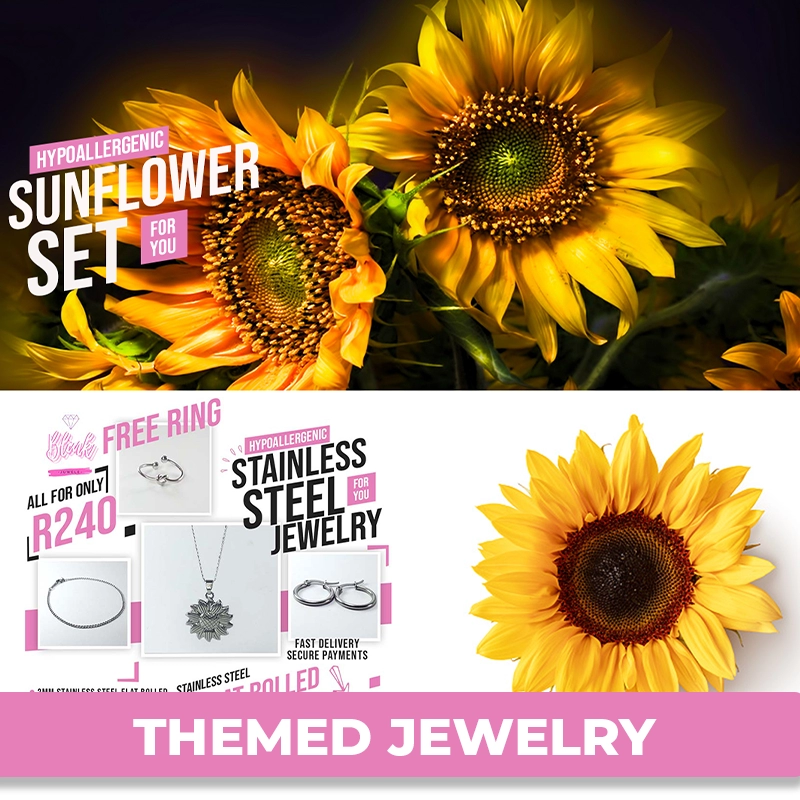

Pretoria’s Largest Selection Of Stainless Steel Jewelry And Men’s Jewelry At The Lowest Prices In SA

We design and manufacture unique quality Stainless Steel Jewelry

Collection in Pretoria East or Ship all over South Africa

Hypoallergenic, non fading for all skin types

Subscribe for 15% Discount

Stainless steel jewelry has become increasingly popular over the years due to its durability, affordability, and sleek design. The process of creating stainless steel jewelry involves several steps, from the initial design to the finished product. Here’s a closer look at the process of creating stainless steel jewelry:

Design

The first step in creating stainless steel jewelry is the design phase. The designer creates sketches or uses computer software to create a 3D model of the jewelry. They consider factors such as the intended audience, style, and functionality of the jewelry.

Prototype

Once the design is complete, a prototype of the jewelry is made. This is usually done with a 3D printer or by hand. The prototype allows the designer to make any necessary adjustments before the final product is produced.

Casting

Once the prototype has been approved, the jewelry is cast. The design is transformed into a mold, and molten stainless steel is poured into the mold. The jewelry is then left to cool and harden.

Polishing and Finishing

After the jewelry has been cast, it is then polished and finished. This process involves removing any rough edges or imperfections from the jewelry. The jewelry is then polished to create a smooth and shiny finish.

Assembly

If the jewelry design involves multiple pieces or elements, they are assembled at this stage. This includes connecting chains, attaching stones, and adding clasps.

Quality Control

Before the final product is shipped to the customer, it undergoes a quality control check. The jewelry is inspected to ensure that it meets the designer’s specifications and that it is free from any defects.

In conclusion, creating stainless steel jewelry is a multi-step process that requires careful attention to detail. From the initial design to the final product, each step is critical in creating high-quality and durable jewelry. The result is a sleek and stylish piece of jewelry that can be worn for years to come.

You might think we’re all about Stainless Steel Jewelry, but #Blink is about change! Changing the way people look. Transforming the way people feel. Changing people’s futures and their lives. Though our fashion-forward Stainless Steel Jewelry are centered on fun, #Blink fulfills a serious mission. We believe that trendy Stainless Steel Jewelry can be available, and affordable, to women (and men) everywhere. We know that wearing a new look, and feeling confident in your appearance, builds amazing self-esteem. Our passion is inspiring dreams, empowering talents, and reaching goals by sharing our products and the excitement of #Blink. We see it happen every day.

Blink Agents/Resellers

This vision is made possible through the reach of #Blink’s Consultants. They’re the ones who bring our original designs to kitchen countertops and boutique shops. Our Consultants bring fun and fashion to everyday life, along with the chance to explore the #Blink opportunity for Jewelry Agents. Find us on Facebook and Instagram